Services

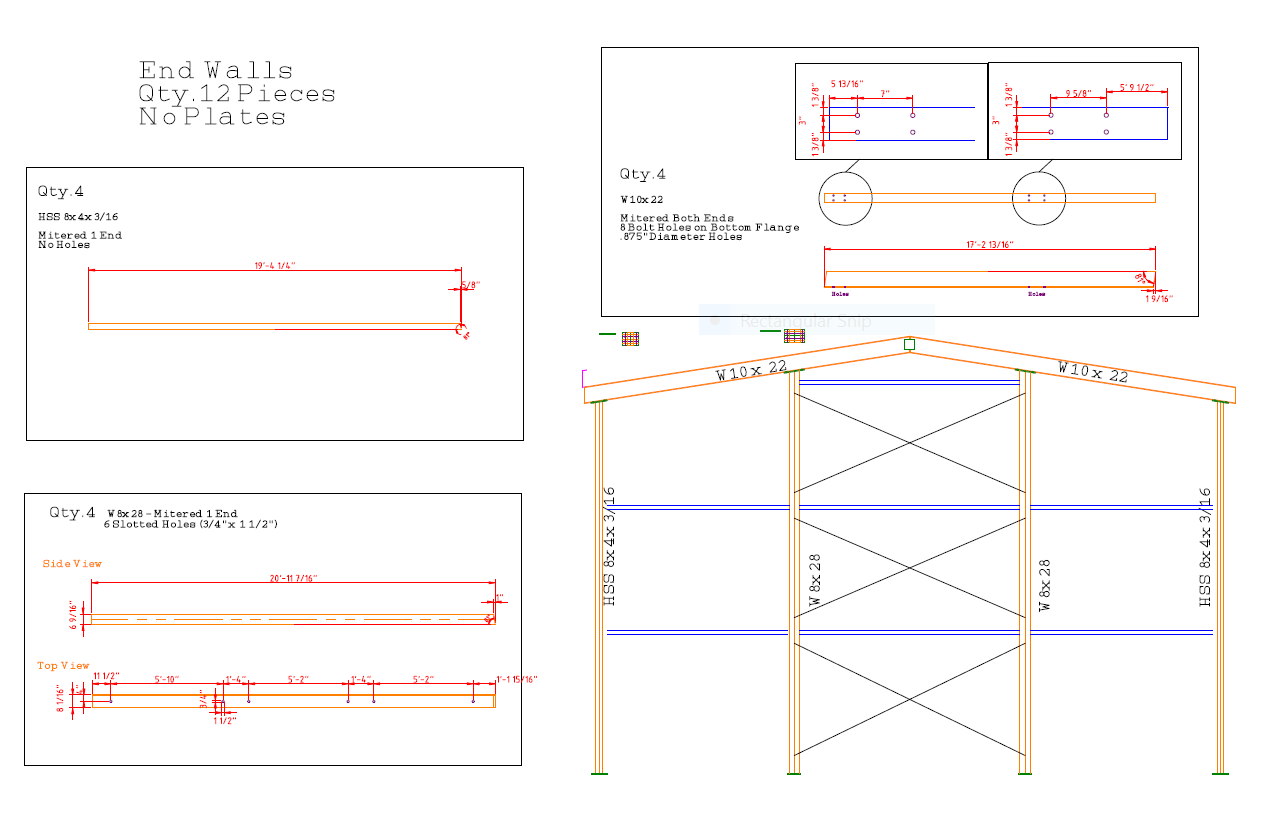

STEEL & ALLOY FABRICATION

Arcline Fabrication’s fully customized metal fabrication services are designed to facilitate clients from wastewater, construction, contractors, food, agriculture, material handling, manufacturing, production, refining, and environmental sectors. We transform wide-ranging materials from stainless steel, aluminum, carbon steel, and many high alloys. Employed are meticulous steps to transform steel sheets, beams, tubing, angle, expanded metal, piping and more, to entirely fabricated components that can be fitted readily into any of your specifications.

STEEL INSTALLATION

Highly skilled and detail-oriented, with a deep understanding of structural steel, blueprints, and safety standards. We install steel accurately and efficiently, ensuring every beam, column, and connection is placed correctly and securely. We work safely under pressure, communicate clearly with engineers and crew members, and consistently meet deadlines without sacrificing quality. We are reliable, precise, and safety-focused, take pride in our workmanship and leave structures that are strong, compliant, and built to last.

CAD DESIGN & ENGINEERING

Does your project require a little more design and detail? We have in house CAD design capabilities and work very closely with a group of multifaceted engineers to deliver on virtually any request.

MECHANICAL SERVICES & MOBILE WELDING

Are you in need of Onsite Mechanical Services and Mobile Welding?

We are a fully outfitted mobile contractor which allows us to be extremely responsive in the event you are seeking professionals to produce quality fabrication, welding, mechanical, piping, millwright, and rigging services.

ASME PIPING

We are ASME Section IX certified!

In-house skilled pipe-fitting and pipe welding. Competitive pricing, accompanied by years of experience with X-Ray quality welds in several petro-chemical facilities. Multiple Weld Procedure Qualifications (WPQ’s) for various base metal and filler metal groups and processes (P#’s and F#’s). SMAW, GTAW, GMAW, FCAW

CNC PLASMA CUTTING

Are you looking for one of the most realized and easy-on-pocket CNC cutting services? You have come to the right place!

Our 5′ x 10′ Arclight Dynamics ArcMax machine is freshly upgraded with all new FlashCut Motors, Controls, and Software. Production cutting from 24 gauge all the way up to .75″ thickness. Pierce cutting up to 1″. Side start up to 1.25″ thickness. We also have Pipe and Tube Cutting capabilities, Seeing eye and tracing capabilities, and CNC pneumatic scribe capabilities.

EQUIPMENT REPAIRS & MAINTENANCE

Vast experience and knowledge in following equipment manufacturer recommendations, and when there may not be a recommended fix from the manufacturer, or repair history, we know how to procure the proper engineering resources to be able to formulate a successful repair plan.

EQUIPMENT RELOCATION

Any equipment, any size, nothing too complex for our experienced and qualified riggers and equipment specialists!

SCAFFOLDING

Experienced in Simple, Complex, Suspended, Cantilevered, and Rolling Work Platform Scaffolding systems. We have our own supply, which makes for quick turnaround on scaffolding needs. Increase in efficiency and decrease in cost.

Equipment

Fabrication

- CNC Plasma Table (5' x 10')

- Durma Primeline 220 Ton x 12' Press Brake

- Marvel Vertical Band Saw 2125A - PC60

- Horizontal Mitering Band Saws

- 50 Ton Iron Worker

- 4' x 10' Fixture Table

- Bridgeport Vertical Milling Machine

- Abrasive Tube Notcher

- Tube Bender

- Hydraulic Ring Roller

- Paint Booth (30' x 35')

- Various Weld Positioners

- Hydraulic Lift Tables

- Various Welding Machines

Installation

- 4 Service Trucks

- Portable Welding Machines

- Deckover Trailer

- Enclosed Job Site Trailer

- Cuplock Scaffolding

- Telescopic Forklift Booms

- Machinery Moving Skates

- Battery Powered Welding Machines

- Battery Powered Mag Drills

- Powered Track Torch

- Pipe Threaders

- Porta Powers

- 3 Plane Laser Line Measuring

- Various Specialty Hand Tools